Defiant Distillers: Revolutionizing whisky production in the Blue Ridge Mountains

Blue Ridge Distilling Company includes (l-r) distiller Eric Meech, office manager Lauren Kuchar, founder and owner Tim Ferris and distiller Joel Patrino. Not pictured is creative solutions specialist Bob Weihe. A chocolate lab named Ridge and a mixed breed named Barley assist with “quality control.”GOLDEN VALLEY —

GOLDEN VALLEY —

More than nine decades after Prohibition, 13 North Carolina companies are distilling and selling their products across the state, from rum and vodka to gin and whisky.

But none of them are quite like Blue Ridge Distilling Company in Golden Valley.

Tucked back on a 100-acre farm surrounded by lush vegetation, flowing creeks and the Blue Ridge Mountains, the distilling company and its one-of-a-kind spirit, Defiant Whisky, was founded in 2010 by Tim Ferris.

A native of Connecticut, Ferris moved to Golden Valley during his high school years. He combined his hobbies of carpentry, plumbing and welding into deep-sea diving, earning his commercial diving certification at age 25 and spending the next 12 years plunging into the ocean.

Three short years ago, Ferris founded Defiant Marine, an international deep-sea diving salvage company consisting of divers, fabricators and welders working at the bottom of the ocean, often in far away lands for months on end. In addition to Ferris, Defiant Marine crew members include Todd Mumma, Dan August, Stryder Claridge and Bob Weihe, the eldest and most experienced of the team.

Ferris said he always wanted to start a distillery, and Defiant Marine is what inspired him to begin distilling a uniquely crafted spirit he named Defiant Whisky, which celebrates one year on the shelves this month.

“‘Spirit’ is a fitting word. I’ve always been interested in how you can put different ingredients together to make something entirely different,” Ferris said. “Distilling is a challenge where fear of the unknown shouldn’t hold you back. Diving has that same spirit, working deep below sea level, blind on the bottom of the ocean and doing impossible tasks with a team.”

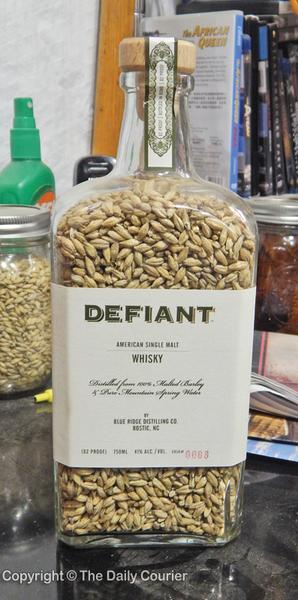

Alyssa Mulliger/Daily Courier Blue Ridge Distilling Company makes all of its own spirit in-house from start to finish, including the labeling and bottling. The 82-proof Defiant Whisky has hints of caramel, honey, vanilla and oak.

As a deep-sea diver, oftentimes the scale and scope is too much for Ferris to take in and requires him to take a step back in order to absorb everything.

“You can’t always plan for what will happen, and it’s the same with distilling,” he said. “You can plan to build a distillery, but you must step back and look at what you can do with that. My dad always said, ‘You can’t steer a still ship.’ It’s not necessarily knowing where you’re going, but getting the water over your rudder.”

In diving and distilling, for Ferris and his crew the first step is making a flawed first step.

“You can’t correct your course before you are on the way,” Ferris said. “It takes trial and error to learn.”

A distillery is born

Alyssa Mulliger/Daily Courier For Blue Ridge Distilling Company, founder and owner Tim Ferris and crew mate Bob Weihe traveled to Germany to select the 1,000-liter, custom-built still made of cooper and stainless still to distill their premium single-malt spirit, Defiant Whisky.

Six years ago Ferris had a small still in his garage and contemplated how to expand upon his hobby.

Once he decided to establish Blue Ridge Distilling Company, his crew members wanted to be involved. The Defiant Marine crew was responsible for the design and building of the distillery, which took less than two years to complete.

Ferris lives in a cabin next to the distillery, where above sea level, his team of home brewers and deep-sea divers turned distillers work to craft their distinctive Defiant Whisky.

Along with Ferris, the distilling company includes distillers Joel Patrino and Eric Meech, office manager Lauren Kuchar, Defiant Marine crew member Weihe who serves as creative solutions specialist, and a chocolate lab named Ridge and mixed breed named Barley who are in charge of “quality control.”

Alyssa Mulliger/Daily Courier According to Blue Ridge Distilling Company founder Tim Ferris, the art of distilling is the fermentation process. Five fermenters are included in the distilling of Defiant Whisky.

For the distillery Ferris and Weihe began with one of the most important parts in the whisky making process: the still. They traveled to Germany and selected a 1,000-liter, custom-built still made of copper and stainless steel to distill their premium single-malt spirit.

The still consists of three parts including the column, pot and condenser, and was assembled by the Defiant Marine crew.

Ferris’ team researched distilling methods and studied countless whisky recipes, purchased high-quality Canadian barley, tested the spring water 220 feet below the distillery’s ground, reviewed the type of oak for aging the whisky and tested the temperatures for distilling the spirit.

“Distilling is something you can’t fake and you can’t cheat,” Ferris said. “It’s the challenge of learning a new process, learning about the art and science that goes along with that process and ultimately becoming pretty good at it.”

Yet the Defiant way is not bound by recipes or tradition.

Ferris and his team are guided by Mother Nature, their intuition and four ingredients: American white oak, specially cultured yeast, two-row premium brewer’s barley and pure water from the aquifer under the distillery.

“We’re rethinking whisky by taking the best of Scottish tradition and combining it with American ingenuity,” Ferris said. “We’re starting a whisky revolution, charting a new course on the journey and we’re doing it the Defiant way.”

The defiant spirit

Blue Ridge Distilling Company makes all of its own spirit in-house from start to finish.

“Everything is done by hand, from cracking the grain to labeling and packaging each batch,” said Patrino, an electrician turned distiller.

Patrino has experience in home brewing and was hired as a head distiller so Ferris would not have to shut down the distillery when out on diving assignments.

“Nobody really taught us about distilling, we kind of taught ourselves,” Patrino said. “We don’t just come in, turn on the machine and that’s it. Every day is different and involves us trying new things and learning new methods.”

Defiant Whisky begins with 100 percent, whole kernel malted barley that is milled on-site, fresh every day. The distillery’s roller mill does not grind the barley, but cracks it.

Alyssa Mulliger/Daily Courier Defiant Whisky begins with 100 percent, Canadian whole kernel malted barley that is milled on-site, fresh every day. The distillery’s roller mill does not grind the barley, but cracks it.

Water is then added to the cracked barley and the mixture is cooked.

“To make a really smooth whisky, the only thing you really want is that sugar water. You don’t want all the husks and all the meat of the grain that is left behind,” Ferris said. “If you can separate it, you’re already starting to make a smoother whisky before it has even gotten to the still.”

The next step is to slowly drain the sugar water and leave behind the grain solids. The distillers then chill the sugar water down to add the yeast and begin fermentation.

For Ferris, this is the most significant aspect of distilling.

“The real art to distilling isn’t the still. The art is the fermentation,” he said. “The still doesn’t make the alcohol, rather it collects alcohol that has already been made during the fermentation process. By focusing on our grain selection, water selection, and yeast selection and how to bring those all together during fermentation, we create a very clean spirit.”

When the fermentation is finished, distillers check the gravity and alcohol content of the product and then pump it into the still where the alcohol is boiled out and the water is left behind. Once the liquor quality becomes good enough, it condenses and drips from the still into a large steel canister.

The dripping liquor is split into three canisters labeled heads, hearts and tails. The heads are tainted, low-quality whisky, the hearts are smooth and buttery whisky which Ferris calls “the good stuff” and the tails are oily whisky. Ferris reruns the tails through the still again and captures the hearts out of them, “making the best whisky that there is.”

After combining the still runs and proofing the liquor down the maturation process begins.

What is normally a five- to 10-year distilling and maturation process, Ferris and his crew achieve in two months. Instead of aging their whisky in barrels, the distillers use stainless steel and add cuts of hand-selected American white oak that is toasted to each made to order batch, creating a smoother finish.

“We focus more on quality than on quantity, which sets us apart,” said Meech, who has a passion for whisky.

Patrino contacted Meech for his whisky making experience, and it was not long before Meech left the Florida beaches and fishing for a living to come work in the North Carolina mountains, turning his passion for distilling into a career.

“I was living in paradise already, but it was time for a new adventure. I love whisky, I love making it,” he said. “The way we make our whisky costs significantly more than some of the bigger distilleries, but we feel that our product is that much better.”

The 82-proof end product has hints of caramel, honey, vanilla and oak. After Defiant Whisky is bottled up it is shipped to waiting, passionate whisky lovers.

Cheers to the future

“Are we your average whisky? No. Are we Jack Daniel’s? No. We are Defiant Whisky,” Ferris said. “Some people like us, and others don’t. Willing to break tradition is the essence of success. Otherwise, you’re just walking in someone else’s footsteps.”

Looking to the future, Blue Ridge Distilling Company wants to get as much of its product into people’s hands as possible.

“We want to be the biggest we can be and sell as much whisky as we can,” Meech said.

Defiant Whisky is sold mainly in the Southeast and along parts of the East Coast. It is currently available in ABC stores as near as North Carolina and Virginia and as far as New Jersey and Rhode Island.

Ferris said he even shipped a few batches to Singapore recently.

The spirit is also available for purchase at ForWhiskeyLovers.com and can be shipped nationwide.

“We’re looking forward to getting to the point where this isn’t enough,” Ferris said. “And I don’t think it’s going to be too far away when we can break ground on a new distillery and all the knowledge that we’ve learned here to be able to make something that’s truly world-class and state of the art.”

Alyssa Mulliger/Daily Courier- Blue Ridge Distilling Company makes all of its own spirit in-house from start to finish, including the labeling and bottling. The 82-proof Defiant Whisky has hints of caramel, honey, vanilla and oak.

Courtesy of The Daily Courier

Story and Photos by: Alyssa Mulliger